video

Contact us

Company£ºSHENZHEN PENGLAI Industrial Corporation Limited

Factory Address£º B406,third floor,Dongmanjidi ,Yijing Road,Luohu district,Shenzhen City, China

OFFICE ADDRESS£º Block A2, First floor,Chaolian Building,838# by 105 National Road,Panyu District,Guangzhou City,China

Contact£ºJack Du

Cel£º +86-15811882441

+86-13077872898

Phone£º +86-20-84206097

+86-755-25423447

Fax£º+86-755¡ª25417648

Email£ºjackdu999@yahoo.com

Skype£ºturnanewleaf

Website£º www.penglaichina.com

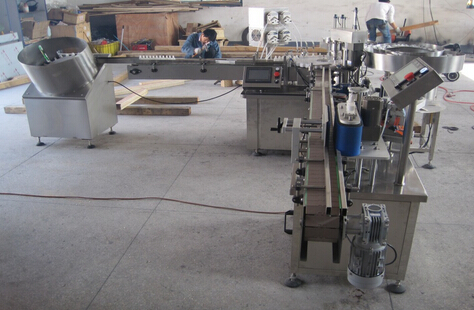

Our small dose bottles filling capping labeling machine is a high-tech product that designed and developed by our company. It suit for different viscosity of liquid, semi-fluid and paste, it is widely used in the product of foodstuff, cosmetics, pharmaceutical, oil, chemical, agricultural and others. Using the straight filling line, can be used in the different container, no need change any parts.

Features of filling capping labeling equipment

It's design compact and reasonable, the appearance is artistic.

Control System- Mitsubishi PLC control system, random change filling volume.

Control Panel- Colorful screen, easy-operated, stable and reliable

Function Improvement- The filling nozzle is equipped with filling blocker. This machine can realize diving filling according to the material properties. (this function can be selected)

Real-Time Alarm- Automatic alarming when the fault happens, automatic stopping and alarming when the system appears serious breakdown.

Performance Improvement- Adopting international famous brand to ensure the remarkable quality, stability and high precision.

Machine Elements- The parts contacted with the material use the high grade SS 304 and non-poisonous. ( Could be SS316 if required )

Expansion Function- We can carry out special configuration according to customers' requirements. (airtight, heating, sterilizing etc)

Counting Detection- Real-time counting, reflecting the output directly.

Filling Detection- No-bottle, no filling, it will not conduct filling if the bottles are not enough.

Maintenance Condition- Fully comply with the GMP requirements, easy to disassemble and clean.

Environmental Protection Configuration- Equipped with eco-friendly frame, realizing more cleaner and sanitary operating environment function and more precise filling measurement.

Changing Specification-No need to change any components, easy to realize changing the bottle types by simple adjusting.

Working Principle

Piston filling machine measures and delivers the product to the container by the action of a single piston for each filling head. On the intake stroke, the piston draws the product from the supply hopper, through the upper check-valve, and into the cylinder of the piston chamber. On the down stroke, the product flows through the lower check-valve , and the product is forced from the chamber through the valve and into the container.

Technic parameters of bottle filling capping labeling machine:

Filling Type

Piston Filling Material Liquid Paste

Filling Temperature Ambient Temperature ( Could Be Thermal If required )

Filling Nozzle Number 2 / 4 / 6 / 8 / 10 / 12...

Filling Volume 5-70ml 10-120ml 25-250ml 50-500ml 100-1000ml

250-2500ml 500-4000ml 500-5000ml

Cylinder Size Depend On Filling Volume

Metering Type Piston Pump

Filling Speed Base On Filling Nozzle Number

Filling Accuracy ±0.5%

Type of Bottles PET, Glass, Tin, Can, Any Kind Container Can Stand-Alone

Air Pressure 0.5-0.7 Mpa

Voltage 220/380V 50/60HZ Three-Phase Four-Wire System

Power 1 KW

Machine Dimension Length 2500 Width 1400 Height 2100 (mm)

Our factory since 1992 has been manufacturing the cosmetic&food making and packaging machinery.In these field we have the experience rich enough to solve the questions encountered by our customers from both home and abroad.For more information about best quality machinery like the filling capping labeling machine,please email via jackdu999@yahoo.com or browse our website www.cosmeticsmachinery.blogspot.com plus www.lianhe666.com/en

Follow us on twitter:http://www.twitter.com/jackdu007

Like us on facebook:http://www.facebook.com/jackdu999

Skype us by :turnanewleaf

Mobile:+86-15811882441

Related video

|

|