video

Contact us

Company£ºSHENZHEN PENGLAI Industrial Corporation Limited

Factory Address£º B406,third floor,Dongmanjidi ,Yijing Road,Luohu district,Shenzhen City, China

OFFICE ADDRESS£º Block A2, First floor,Chaolian Building,838# by 105 National Road,Panyu District,Guangzhou City,China

Contact£ºJack Du

Cel£º +86-15811882441

+86-13077872898

Phone£º +86-20-84206097

+86-755-25423447

Fax£º+86-755¡ª25417648

Email£ºjackdu999@yahoo.com

Skype£ºturnanewleaf

Website£º www.penglaichina.com

Model YX -100 PVC Sleeve Shrink Label Machine for plastic water bottles high speed shrinking sleeve labeler

Sleeve labeling machines with steam shrink tunnel

1) Features;

a. Various bottle type;round, square and so on.

b. High precious location;save cost and correct.

c. Suitable for adjustment inside film range from 3′to 10′.

d. Man-machine conversation liquid crystal screen;easy operation

e. Magic Eye control feeding material, automatically.

f. PLC control system

g. High- speed sleeve film.(Temperature; from 100 to 600°C suitable for various film material

h. Screw transportation located system;Location for various shape bottles.

i. No need tool adjustment

Automatic shrink sleeve labeling machine, with steam shrink tunnel and generator ,PVC,PET lable machine

1 Synchronized transmission, any change of transmission belt will be finished quickly. Compared to the type of traditional multilayer whose change and maintain need more than six hours, its maintenance is easy and maintain is simple, so it doesn't influence production.

2 Unit cutter head plane design in China which apply to the container of 30mm—130mm.you never need to change

or debug it. It also has unique light touch human-machine screen, that means,auto search original location as well as safety and convenience which is aheadof other congener products.

3 Single shrinking label feed plane ,reasonably height which is convenient to fix the label; micro-computer auto figure which avoid enactment and adjustment .you only need to press it lightly ,the label will detect and locate automatially.The change of label is quick and convinent,besides,the cut place is absolutely exact .

4 Label feeding equipment;driving synchronized tensility control the supply of label ,the supply ability is 90meters per minite,volume

label supply plane is 500mm,the internal diameter of paper tube will be 4' ,8',10' .the configuration of label feeding is stable tensility which enable the exact length of label and the stable ,quick supply of label.

5 The center pillar applies step by step shoot label structure and the speed is 150B per minute.

6 The newly designed cutter head use step by step motor driving which speed is high, action is exact, the cut is in order and the shrinking is beautiful. This design cooperates with the label synchronized location structure enable the precision of cut location within 1mm.

7 Many emergency stop buttons enable emergency stop at the proper position along the production which guarantee the safe production.

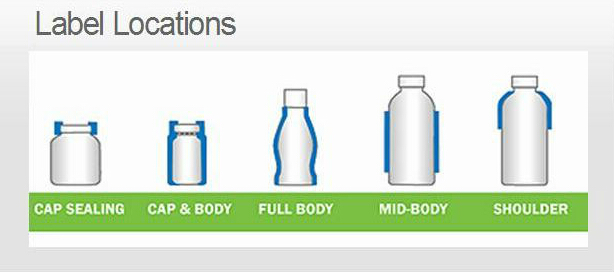

Label locations for different bottles according to different requirements

Main technical parameters of the sleeve labeling equipment:

Voltage;

1 Host machine; AC220V, 50/60HZ, 1.5-2KW, single-phase

2. Production speed;7000-9000 b/h

The standard length of label is 100mm

and the speed can be adjusted accord to customer's requirements. The speed will be faster if the label is shorter.

4. Diameter of bottle body; 28mm-125mm

5. Length of label;30mm-250mm

6. Thickness of label;0.035mm-013mm

7. Material of label;PVC, PET, OPS

8.label material:pvc,pet,ops

9.shrink machine size:2100*850*2000mm

steam pressure:1kg/cm2

steam:50kg/h

steam furnance size:2000*500*1700mm

host machine;L2000MM*W850MM*H2000MM

Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse , misapplication, storage damage, negligence, or modification to the Equipment or its components.

ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine (The time of train depend on you worker).

The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. also you can go to our factory to do training.

After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.(as above).

Our Factory since 1992 has been manufacturing the cosmetic&food making and packaging machinery.In these field we have the experience rich enough to solve the questions encountered by our customers from both home and abroad.For more information about various high quality machinery like Automatic shrink sleeve labeling machine, with steam shrink tunnel and generator ,PVC,PET lable machine,please email via jackdu999@yahoo.com or browse our website www.cosmeticsmachinery.blogspot.com.

Follow us on twitter:http://www.twitter.com/jackdu007

Like us on facebook:http://www.facebook.com/jackdu999

Skype us by :turnanewleaf

Call us via:0086-15811882441

PENGLAI INDUSTRIAL CORPORATION LIMITED

Related video

|

|