video

Contact us

Company£ºSHENZHEN PENGLAI Industrial Corporation Limited

Factory Address£º B406,third floor,Dongmanjidi ,Yijing Road,Luohu district,Shenzhen City, China

OFFICE ADDRESS£º Block A2, First floor,Chaolian Building,838# by 105 National Road,Panyu District,Guangzhou City,China

Contact£ºJack Du

Cel£º +86-15811882441

+86-13077872898

Phone£º +86-20-84206097

+86-755-25423447

Fax£º+86-755¡ª25417648

Email£ºjackdu999@yahoo.com

Skype£ºturnanewleaf

Website£º www.penglaichina.com

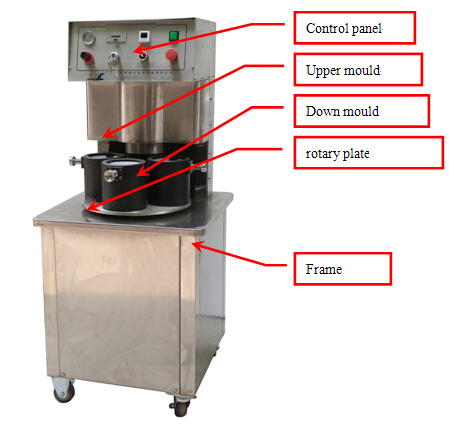

This machine,vacuum capping machine 4 heads semi automatic glass jars la limitación de vacío de la máquina, is consisted of machine frame, upper mould down mould, capping structure, vacuum system, electric and pressure control system. Working as: put the glass with caps into the down mould, then put the down mould down to the center of the capping head by hand. Then the machine will be automatically capping with vacuum.

This machine vacuum capping machine 4 heads semi automatic glass jars la limitación de vacío de la máquina has below functions as£º

2.1£®1¡¢when you put the down mould to the center of the capping head, the machine will automatically capping with vacuum£»

2.1.2¡¢The lowest vacuum set function: if the machine can not reach

the vacuum degree as set before, the machine will not working for the next procedure£»

2.1.3¡¢capping torque function£º The capping head is moved by air cylinder, and can be adjusted by pressure£»

£¨2£©Main structure and components£º

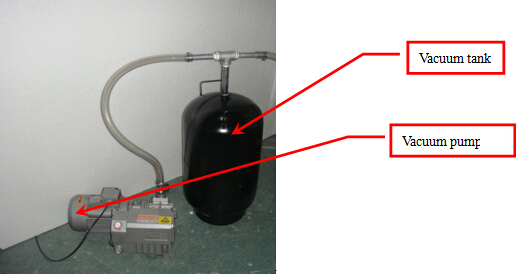

2.2.1¡¢ Vacuum pump and vacuum tank£ºVacuum pump and vacuum tank is used to achieve vacuum function, the vaccum pump should be with vacuum oil, half of vacuum oil inside is ok. Not allowed to use the machine if there is no more vacuum oil inside.

Pls connect the vacuum pump and vacuum tank as above picture and supply power

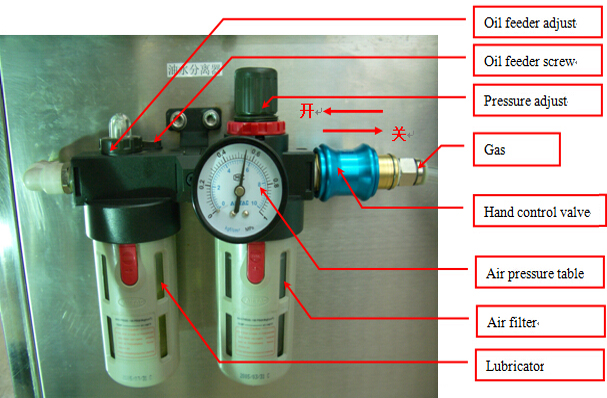

The capping head is moved by cylinder to lift and down, when the capping head is down to capping and reach the vacuum degree as set before, the capping head will move to the next procedure. The capping torque can be adjusted by capping pressure button on the control panel(As you can see in the control panel)

The red rubber inside the capping head is the easy wear part, need to check and change often. When capping, the capping head must put tight to the caps, you can put something inside the down mould to achieve different heights. But the height can not be too much, or if it is too height, you can not achieve vacuum function, but if it is not enough height, it can not be capped. Usually the distance for the caps and top of the down mould is 16mm-19mm.

When the down mould is pushed into the center of the capping head, the down mould to position detect has a signal, then the bottle holding cylinder hold the bottles tightly, the upper mould will be down to capping with vacuum, when finish, will to move to the next procedure.

Main technical parameter OF vacuum capping machine 4 heads semi automatic glass jars la limitación de vacío de la máquina:

Model YX-30B

Power supply: AC220V/50-60Hz

Capping speed: 1200-1500bph

Power: ≤1.3KW (include vacuum pump)

Cap diameter: Φ30-Φ85mm ¡¢Φ85-Φ110mm

Bottle height: 50-180mm ¡¢120£250mm

Bottle diameter: Φ30-Φ80mm Φ80-Φ150mm

Limiting vacuum degree: -0.08Mpa

Capping torsion: 5-25N.M

Air consumption: 0.5m3/0.7Mpa

For more information about the various machines like vacuum capping machine 4 heads semi automatic glass jars la limitación de vacío de la máquina filling packing equipments from our superb cosmetic machinery factory,plz browse our another website business video http://youtube.com/user/mrjackdu007 as well as follow PENGLAI INDUSTRIAL CORP business website http://penglaichina.com

PENGLAI INDUSTRIAL CORPORATION LIMITED

Related video

|

|